As a leading heat treatment service provider, Specialty Steel Treating is committed to offering precision treatment services for a variety of needs. Understand how quenching and tempering steel can offer you the innovative steel characteristics you need for your manufacturing process, and why we’re the leaders in this steel treatment option. Enjoy high-performance steel that balances hardness and ductility today.

The Quenching Process

It all starts with heated steel. Depending on the speed and temperature of your steel cooling process, you’ll receive various grain structures. Here are just a few common grain structures that your austenitic steel grain structure can transform into as it cools:

- Pearlite

- Ferrite

- Martensite

- Cementite

- Bainite

The quenching process can use salt water, forced air, polymer, fresh water or oil. Oil quenching is a common method that we use at Specialty Steel Treating to avoid boiling and produce longer cool times. Other quenching options cool steel too quickly for many applications.

Salt water is the fastest option for rapidly cooling your heated steel. While a rapid cooling process may cut down on production time, this severe quenching option can often lead to cracked steel or a poor grain structure.

While tempering can alter the characteristics of your steel, quenching plays a crucial role in the final specifications of the project. Don’t choose a particular quenching option due to time or money restrictions, but carefully research the best option available and discuss your engineering needs with a qualified steel treatment service provider.

Tempering Steel

After quenching, your steel will be brittle and hard. Most steel applications require a more ductile material, so your steel must be tempering. By sacrificing some of the hardness, you can create a balance between hard, ductile material.

Typically, tempering steel occurs with temperatures between 400 and 1,105 degrees Fahrenheit. Some tempering can further increase ductility with temperatures as high as 1,300 degrees Fahrenheit.

The tempering process requires incredibly precise steel treatment to avoid any flaws in the craftsmanship. When you choose a leading tempering service provider, your steel will be less brittle, easier to weld, more ductile and have improved resistance to abrasion.

As a leader in quenching and tempering, our team understands the necessity of complete precision and control throughout the process. We use oil quenching for superior control, reduced cool down times and high-quality steel products. Depending on your steel needs, we’ll work with you to determine the best temperature and time specifications, then deliver precision components that meet your needs and your deadlines.

Common Quenching and Tempering Applications

Use quenched and tempered steel to create a variety of precision components for your equipment or manufacturing facility. From deflector plates and storage tanks to building materials and saw cutting edges, quenched and tempered steel is used in diverse applications depending on the quality of the material and the specific grain structure achieved through quenching and tempering.

Understanding the TTT Diagram for Steel

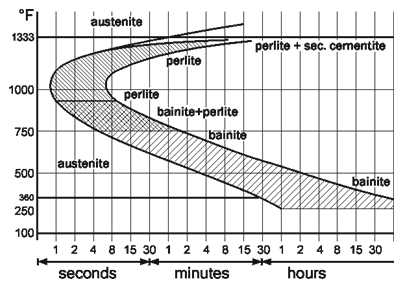

To understand exactly how your steel needs to be quenched and tempered, we use a time, temperature and transformation diagram, or TTT diagram for steel. This useful diagram compares the different grain structures achieved through different starting temperatures and cool times.

A rapid cool down might leave you with far more austenitic grain structure, while a slow, low-temperature cool down could result in more bainite structure. Determine the various benefits of each structure and work with a steel treatment provider who can assist you in finding the ideal quenching and tempering specifications for your unique project.

Learn More and Request a Quote Today

When you’re ready to receive industry-leading tempering steel services, contact us at Specialty Steel Treating today. From aerospace and automotive to industrial and heavy equipment, we work with a variety of industries to provide cutting-edge steel treatment services.