The Benefits of Annealing

Annealing steel or any other metal involves heating it to a specific temperature and allowing it to cool at a specified rate. Doing so removes impurities in the grain, increasing the metal’s ductility and reducing its hardness.

Today, the process of annealing steel and annealing metals is used in many industrial applications where the metal must be at the highest quality. The process has been enhanced with modern machinery to the degree that now the legendary durability of the samurai katana can be achieved in many industrial metals.

A Summary of the Annealing Process

A piece of metal is composed of a lattice of crystal structures known as grains, and sometimes these grains align in such a way that they cause additional stress to the metal piece as a whole. In the first stage of annealing steel or other metals, known as recovery, the metal is heated to a point at which these internal stresses can dissipate.

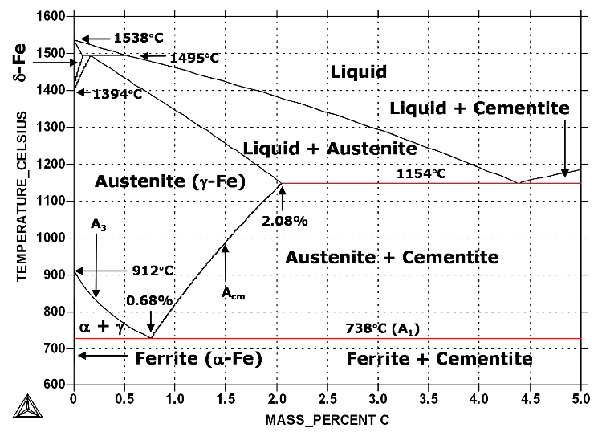

Further heating the metal to just below its melting point allows new grains to form that don’t have the preexisting stresses of the old grains. This formation of new grains is called recrystallization. In order to control the growth of these new grains, the metal is allowed to cool at a specific rate, in what we call the grain growth stage.

The completion of this entire process results in metal with superior ductility and reduced hardness. Why is it sometimes better to have metal with reduced hardness? If a piece of metal is too hard, that makes it brittle. The most durable metals have high ductility, which means that they can bend and absorb impacts without breaking. Annealing metals is a way to achieve this much-desired balance between hardness and ductility.

Industrial Uses of Annealed Metal

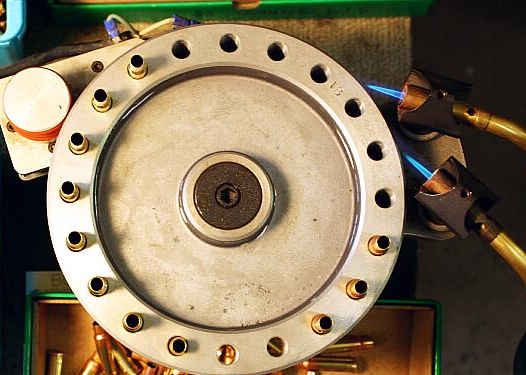

Many of the industrial processes that are common today require or are enhanced by using annealed steel and annealed metals. For instance, to reduce the residual stresses of welding, often the welded structure is treated with an annealing process.

Annealing can also strengthen metal that has been super-heated through high-intensity machining. When a metal wire is drawn thinner, it can cause stresses in the grains, and as such, new metal wires will often be annealed. Additionally, the process of making sheet metal can create a piece with too much hardness, so sheets are often annealed to restore their durability.

How Exactly Does Annealing Change the Behavior of Metals?

So what are the actual results of annealing metal to increase its ductility and lower its hardness? A piece of metal can crack or even break if it is left with residual stresses, and since annealing removes these residual stresses, it can help metal keep its shape.

Annealing steel is also helpful to improve the lifespan of machining tools. Working a brittle piece of metal can cause additional wear on tools, whereas a highly ductile piece of metal will minimize the damage to the tools caused by constant use. The last benefit is something you may have already inferred: Annealing metals allows them to be more easily bent and formed into your desired shapes.

Annealing vs Normalizing

When talking about heat treatment of metal, there are typically two processes discussed at length: annealing vs normalizing. However, before diving into the specifics of each method as well as the benefits of one treatment over the other, it is necessary to understand why you would heat treat metal in the first place.

Why Heat Treat Metal?

There are several reasons companies want their metal to undergo a heat treatment process. For example, one of the most apparent reasons to treat metal is to improve the overall strength and quality of the material. When diving into more specific purposes, companies might want improved hardness, corrosion resistance, toughness, and ductility. Depending on the desired outcome of the steel or metal, companies will choose one of several treatment options, with the top two options being either annealing or normalizing.

What Is Annealing?

When annealing steel, the material is heated to a specific temperature, which is predefined by the type of steel being used. Once heated, the material is cooled in a conditioned atmosphere, like the furnace where it was heated.

The purpose of annealing is to increase ductility and machineability by improving the toughness of the substance and improving the softness. There are several forms of annealing, like recrystallization, stress relief, spheroidizing, process and full annealing. Each process is designed for a specific function and result.

What Is Normalizing?

Counter to annealing metal, normalizing is about increasing hardness. This is accomplished by heating the material above the austenitic range, and then allowing it to cool in the air, which results in rapid cooling. This process also results in less ductility.

Other Processes

Beyond annealing and normalizing, there are at least two other conventional treatment options for steel and other metals: tempering and quenching. Each option is popular among many manufacturing and production companies. However, there are specific purposes, advantages and disadvantages to using each, just as there is with annealing and normalizing.

- Tempering

Tempering, like annealing, is used to improve the ductility and softness of the material. However, this treatment method puts a more significant emphasis on increasing the magnetic properties as well as the cutting properties of the steel.

- Quenching

Quenching is similar to tempering in that the cutting and magnetic properties are increased. However, the focus on this treatment process is to improve the hardness of the material, like in normalizing. Unlike normalizing, where the metal is air-cooled, quenching utilizes a liquid medium to cool the steel rapidly. Through this process, the grain of the steel is made finer because it is not allowed to grow after nucleation.

Whether you are looking to heat treat your steel through normalizing or full annealing, Specialty Steel Treating is ready to handle all of your treatment needs. Although, if you are not yet sure of the process that best suits your needs, then contact one of our representatives to discuss the benefits of annealing steel and the treatment processes and the specifics of your particular project.

Your Heat Treatment Specialists

If you think that your operation would benefit if you took your metals through the annealing process, talk to our experts here at Specialty Steel Treating and we will make our recommendation. Our state of the art heat treating process will provide amazing results.