Specialty Steel Treating is a leading precision steel heat treatment company that has more than 60 years of experience working with commercial clients and heat treated steel in many industries. Our mission is to perform high-quality precision controlled heat treating to maximize productivity and lower manufacturing costs.

Some of the steel and metal heat treatment services we offer include: tempering steel, case hardening, oil quenching, steel heat treatment, precipitation hardening, vacuum heat treatments and more.

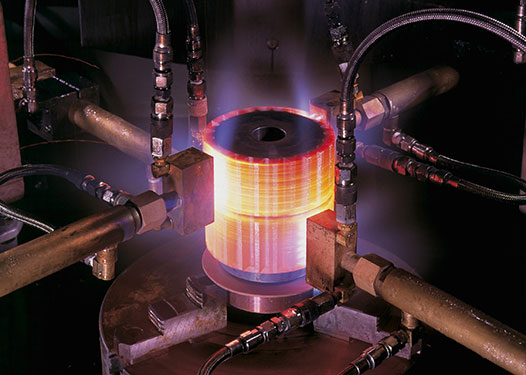

Vacuum Treatments

During our vacuum heat treatments, steel is austenitized through a process of applying varying high temperatures to the metal in conjunction with the use of a partial or hard pressure vacuum in order to protect the material and shorten processing time. This leaves the finished product less susceptible to corrosion, oxidation and wear, while improving strength and durability.

Case Hardening

The process of case application uses diffused carbon to strengthen steel by forming a casing which surrounds the material. This allows the outside to be tough without unnecessarily hardening the entire product throughout. Case application treatments can be applied to a range of metal parts, including high alloy and low-carbon steel pieces.

Oil Quenching

Heat treating via the oil quenching process involves immersing already appropriately heated steel in an oil, different depending on the type of material used, so that the metal can completely harden. Usually, products are subsequently worked through tempering, stress relieving, or aging procedures as a way to achieve the final desired outcome.

Secondary Treatments

Metals can be made stronger through a number of secondary methods, as well. Annealing, tempering, stress relieving, deep freezing and cryogenics techniques can all help make products more resilient and workable.

Heat Treated Steel and How To Avoid Problems

It is not uncommon for one to experience problems after heat treating metals. Although it is one of the last stages during the manufacturing process, it is no less important. When done properly, heat treatment can alter the mechanical and physical properties of metals without changing their shape. When done wrong, the results are less than desirable. You want to ensure that the material is high-quality by avoiding steel heat treatment problems. Here is some information on common heat treatment problems and how to avoid them.

Overheating and Burning

Low alloy metals and decarburization can cause overheating and burning. Temperatures higher than 1200 °C destroys steel and other low alloy metals. Some deterioration in mechanical properties can occur if the heat treatment is administered prior to forging and other mechanical processes. Mechanical deficiencies that occur from using too much heat can affect the treated metal’s toughness and impact strength. A mechanical deficiency can cause the orange peel effect. The orange peel effect is when the surface has hard and soft spots all over it.

It is possible to reverse the effect of overheating and burning with careful temperature control. The correct temperature is necessary to ensure that uneven heating does not occur. Other ways to correct overheating include checking the tools to ensure they are protected with the right anti-decarburizing solutions and the metal to ensure that even heating has occurred. If the metal is unevenly heated, usually because preheating did not occur, the remedy is to allow the metal to slowly cool before reheating and hardening it.

Brittleness

Brittleness is another problem. Applying too much heat causes this problem. To correct brittleness issues, it may be necessary to temper the metal for a shorter length of time and to lower the hardening temperature. You can correct brittleness by increasing the hardening temperature and time if the problem is causing improper tempering and too much hardness.

Wrong Type of Metal

Not all alloys are suitable for heat treatment. The wrong alloys create metal that doesn’t have sufficient impact strength. Bear in mind that many factors can affect the impact strength of metal, but not as much as the number and type of impurities it contains, its surface condition and if any thermal and mechanical treatments were administered.

Warping and Deformation

Normalize treated metal prior to heat treating, to avoid warping. An even temperature and sufficient time are necessary. Maintain the furnace temperature throughout the entire treatment process. Proper stabilization of the metal to prevent movement during the quenching process can also help to prevent warping. It is important to time each step. The right temperatures are achieved when you time each step. If there are stresses present before the heat treatment process, they can create issues with formation and warping. Use sufficient stress relieving measures, when machining is complete.

Uneven Hardness

Uneven hardness is a common problem, which occurs when steam bubbles form during the cooling process, there is too much carbon on the tools and the metal’s surface was not sufficiently cleaned before treatment. To correct the issue, it may be necessary to use a different dipping process, thoroughly clean all tools and metal surfaces and to stir the bath before heating.

Cooling Fractures

Cooling fractures are very common when there is uneven heating, rapid cool down and overheating. Preheat metal to the right temperature to ensure that it heats evenly. One must consider the hardness capacity of the worked on metal. Tool selection should occur based on the metal’s hardenability and shape.

It is possible for fractures to occur during the quenching process prior to tempering, resulting in incomplete transformation. Common causes include cold tools and residual austenite. Tempering the metal right after the hardening process and completing the transformation with treatment can help prevent cooling fractures.

Preventing Heat Treatment Problems

Prevent steel heat treatment problems by using these techniques: vacuum furnaces, proper hardening, quenching, tempering and molten salts. Oxidation and decarburization can occur when air, certain furnace types, or combustion products are present. This leads to quality issues with surface, dimension, and strength.

Contact Specialty Steel Treating to find out more about how our metal heat treating services can help you.